Armstrong 814/815/816 Inverted Bucket Steam Trap features cast iron body with horizontal installation and side-in side-out design. Suitable for steam mains, tracing lines, and steam equipment, offering efficient condensate drainage, stable reliability, water hammer resistance, and automatic non-condensable gas venting. Max differential pressure 1.7MPa, max capacity 9072kg/h, reducing maintenance costs and saving steam energy.

The 814/815/816 Inverted Bucket Steam Trap is a highly efficient and reliable drainage device from Armstrong, featuring cast iron body construction with horizontal installation and side-in side-out design. This type of steam trap is recognized as one of the most reliable steam traps available, capable of meeting the drainage requirements of virtually all steam mains, tracing lines, and steam equipment.

Its core advantage lies in the inverted bucket's ability to operate stably within the cast iron body over extended periods, reducing equipment maintenance frequency and costs while minimizing steam energy waste. The unique structural design provides water hammer resistance, continuous condensate discharge without accumulation, and automatic venting of non-condensable gases such as air and carbon dioxide, ensuring efficient steam system operation.

| Parameter | Value |

|---|---|

| Max Working Differential Pressure | 1.7MPa |

| Max Allowable Pressure (Shell) | 1.7MPa @ 232°C |

| Max Capacity | 9072kg/h |

| Installation | Horizontal |

| Flow Direction | Side-In Side-Out |

| Connection Type | Threaded, Carbon Steel Flanged |

| Test Plug Material | Carbon Steel |

| Model | Nominal Diameter (DN) | Test Port Size (DN) |

|---|---|---|

| 814 | 25, 32 | 25 |

| 815 | 25, 32, 40, 50 | 40 |

| 816 | 50, 65 | 50 |

| Component | Material |

|---|---|

| Body | ASTM A48 CL30 Cast Iron |

| Internal Components | 304 Stainless Steel |

| Disc and Seat | 17-4PH H900 |

| Test Plug | Carbon Steel |

| Flange (Optional) | Carbon Steel |

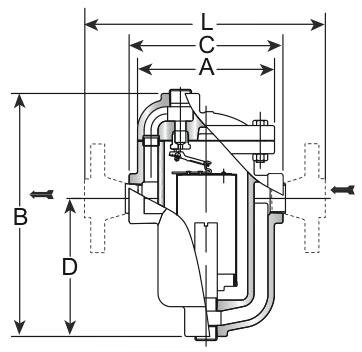

| Model | DN | A | B | C | D | HG20592 PN25 RF (L) | ASME B16.5 CL150 RF (L) | Bolts |

|---|---|---|---|---|---|---|---|---|

| 814 | 25 | 203 | 346 | 229 | 198 | 310 | 310 | 8 |

| 814 | 32 | 203 | 346 | 229 | 198 | 350 | 350 | 8 |

| 815 | 25 | 229 | 413 | 60 | 205 | 350 | 350 | 8 |

| 815 | 32 | 229 | 413 | 60 | 205 | 350 | 350 | 8 |

| 815 | 40 | 229 | 413 | 60 | 205 | 350 | 350 | 8 |

| 815 | 50 | 229 | 413 | 60 | 205 | 350 | 350 | 8 |

| 816 | 50 | 292 | 541 | 330 | 279 | 500 | 500 | 8 |

| 816 | 65 | 292 | 541 | 330 | 279 | 500 | 500 | 8 |

| Model | DN | Threaded | Flanged (HG20592 PN25 RF) |

|---|---|---|---|

| 814 | 25 | 20.9 | 22.6 |

| 814 | 32 | 20.9 | 24.2 |

| 815 | 25 | 32.2 | 34.8 |

| 815 | 32 | 32.2 | 36.2 |

| 815 | 40 | 32.2 | 37.0 |

| 815 | 50 | 32.2 | 38.6 |

| 816 | 50 | 59.4 | 66.4 |

| 816 | 65 | 59.4 | 68.6 |

Note: Weights are approximate. Flanged connection weights are based on HG20592 PN25 RF standard; consult supplier for other standards.

The 814/815/816 Inverted Bucket Steam Trap offers the following optional configurations. Add the corresponding suffix to the model number when ordering:

When ordering, please clearly specify the following information to ensure the product meets your requirements:

Note: Design, materials, weight, and performance specifications are approximate and subject to change without notice.

This product is suitable for various steam systems, including but not limited to:

Explore similar products in our catalog