Armstrong 800/811/812/813 Inverted Bucket Steam Trap, cast iron construction designed for horizontal installation, maximum working pressure up to 250 psig (17 bar), maximum capacity 4,400 lb/hr (2,000 kg/hr). Features efficient condensate discharge, continuous automatic air venting, water hammer resistance, and serviceability, suitable for various steam equipment, reducing maintenance costs and achieving energy savings.

Armstrong 800/811/812/813 Inverted Bucket Steam Trap is a high-efficiency drainage device constructed from cast iron, specifically designed for horizontal installation. As one of the most reliable types of steam traps, the inverted bucket design enables efficient condensate discharge for various steam equipment. This series features long-lasting stable operation, significantly saving energy while reducing replacement and labor costs. All models are serviceable, further minimizing maintenance expenses.

The unique lever system amplifies the force generated by the bucket, ensuring smooth valve opening under system pressure. The free-floating mechanical structure has no fixed pivot points, avoiding wear and friction issues. Since the mechanical components are located at the top of the trap, the orifice does not accumulate debris. Fine particles remain suspended in the fluid and are expelled through full differential pressure blowdown when the bucket sinks and the valve lifts off its seat. A water seal around the orifice prevents fresh steam leakage, while a small vent hole in the bucket enables continuous automatic venting of air and CO₂ at steam temperature. Although this series operates with intermittent discharge, it achieves continuous drainage without condensate accumulation and provides water hammer resistance.

| Parameter | Value |

|---|---|

| Max Allowable Pressure for Vessel Design | 250 psig @ 450°F (17 bar @ 232°C) |

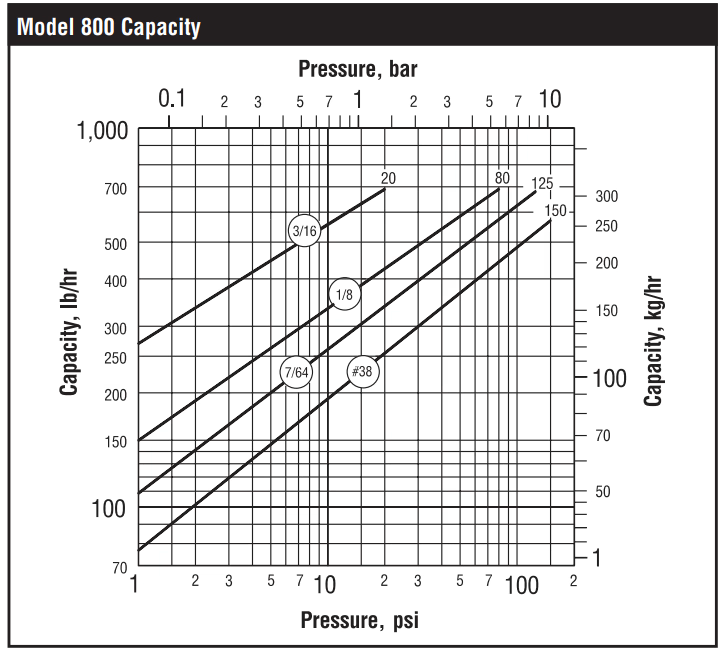

| Max Working Pressure (Model 800) | 150 psig (10 bar) |

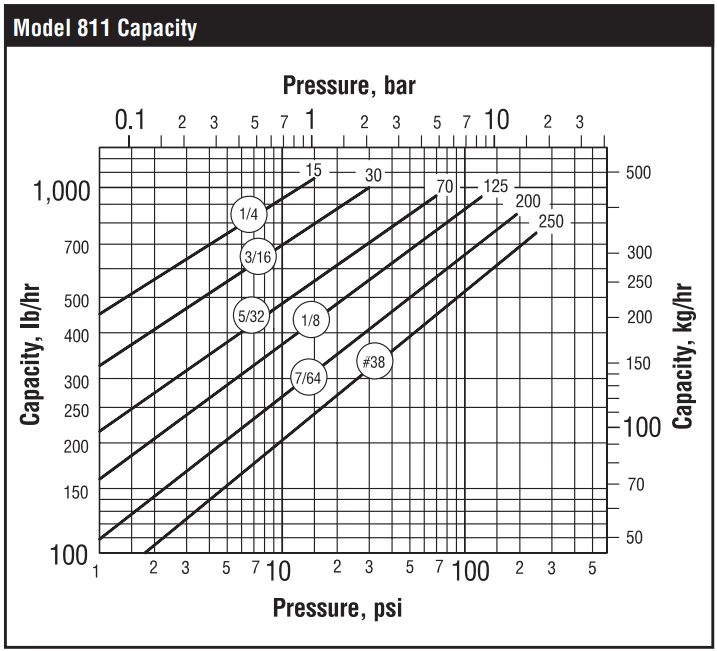

| Max Working Pressure (Model 811-813) | 250 psig (17 bar) |

| Max Capacity | 4,400 lb/hr (2,000 kg/hr) |

| Component | Material |

|---|---|

| Body | ASTM A48 Class 30 Cast Iron |

| Internal Components | 304 Stainless Steel |

| Disc and Seat | 17-4PH Hardened Chrome Steel |

| Test Plug | Carbon Steel |

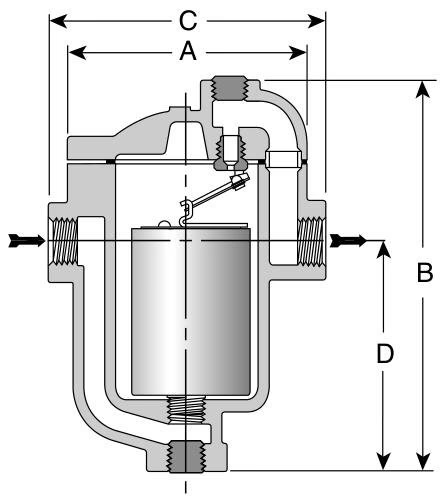

| Model | Pipe Connection (in/mm) | Test Plug (in/mm) | Flange Dia. "A" (in/mm) | Height "B" (in/mm) | Face-to-Face "C" (in/mm) | Bottom to C Inlet "D" (in/mm) | Bolts | Weight (lb/kg) |

|---|---|---|---|---|---|---|---|---|

| 800 | 1/2, 3/4 / 15, 20 | 1/4 / 6 | 3-3/4 / 95.2 | 5-7/16 / 138 | 5 / 127 | 2-3/4 / 70 | 6 | 5 (2.3) |

| 811 | 1/2, 3/4, 1 / 15, 20, 25 | 1/4 / 6 | 3-3/4 / 95.2 | 6-7/8 / 175 | 5 / 127 | 4-1/4 / 108 | 6 | 6 (2.7) |

| 812 | 1/2, 3/4 / 15, 20 | 1/2 / 15 | 5-5/8 / 143 | 9-1/16 / 230 | 6-1/2 / 165 | 5-3/8 / 137 | 6 | 15 (6.8) |

| 813 | 3/4, 1 / 20, 25 | 3/4 / 20 | 7 / 178 | 11-3/4 / 298 | 7-3/4 / 197 | 7-1/32 / 179 | 6 | 27-1/2 (12.5) |

Note: Model 800 cannot be equipped with both thermostatic air vent bucket and check valve simultaneously

Inverted bucket steam trap, cast iron construction, with continuous air venting at steam temperature, featuring free-floating stainless steel mechanism with orifice located at the top of the trap.

When ordering, please specify:

For detailed certification drawings, refer to CD #1000.

Explore similar products in our catalog