TLV J3X/JF3X series free float steam trap with thermostatic air vent, ductile iron/cast iron construction with reliable sealing, single float maintenance-free design, built-in strainer, in-line maintainable internals, suitable for small process equipment, compatible with various pressure and temperature conditions.

TLV J3X/JF3X series is a free float steam trap equipped with a thermostatic air vent, constructed from ductile iron or cast iron with tight sealing and reliable performance, specifically designed for small process equipment. The product achieves continuous, smooth, low-velocity condensate discharge through a self-adjusting free float, combined with a thermostatic bellows (X-element) that automatically vents low-temperature air. The built-in large flow area strainer ensures trouble-free operation, and in-line maintainable internals significantly reduce maintenance costs and downtime.

| Parameter | J3X Series | JF3X Series |

|---|---|---|

| Connection Type | Threaded (NPT and other standards available) | Flanged (DIN and other standards available) |

| Size (mm) | 15, 20, 25 | 15, 20, 25 |

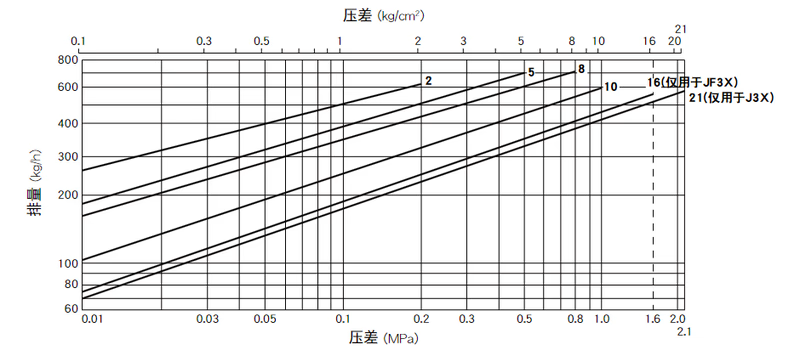

| Orifice Number | 2, 5, 8, 10, 21 | 2, 5, 8, 10, 16 |

| Max Operating Pressure (MPaG) | 0.2, 0.5, 0.8, 1.0, 2.1 | 0.2, 0.5, 0.8, 1.0, 1.6 |

| Max Differential Pressure (MPa) | 0.2, 0.5, 0.8, 1.0, 2.1 | 0.2, 0.5, 0.8, 1.0, 1.6 |

| Min Operating Pressure (MPaG) | 0.01 | 0.01 |

| Max Operating Temperature (°C) | 220 | 220 |

| Max Allowable Pressure (MPaG) | 2.1 | 1.6 |

| Max Allowable Temperature (°C) | 220 | 220 |

| X-Element Type | Standard C6, optional C11 (*) | Standard C6, optional C11 (*) |

| X-Element Subcooling (°C) | Within 6, optional within 11 | Within 6, optional within 11 |

Note: * When selecting C11 type X-element, steam trap capacity will be slightly reduced. Contact TLV for details; 1MPa = 10.197 kg/cm².

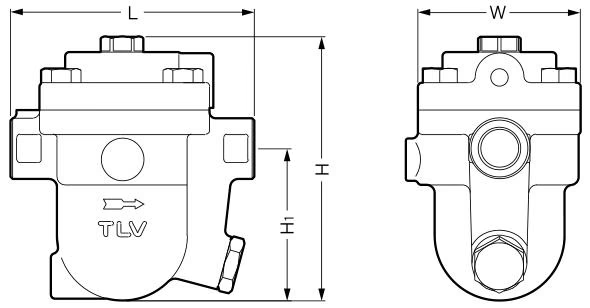

| Size | L | H | H₁ | W | Weight (kg) |

|---|---|---|---|---|---|

| 15 | 120 | 130 | 75 | 80 | 2.7 |

| 20 | 120 | 130 | 72.5 | 80 | 2.8 |

| 25 | 120 | 137 | 75 | 80 | 3.0 |

Note: Thread standard defaults to NPT; other standards available on request.

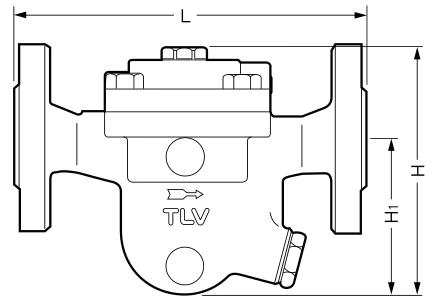

| Size | L (ASME) | L (ASME) | L (ASME) | L (ASME) | H | H₁ | Weight* (kg) |

|---|---|---|---|---|---|---|---|

| 125FF | (150RF) | 250RF | (300RF) | ||||

| (15) | — | 175 | — | 175 | 130 | 80 | 3.8 |

| (20) | — | 195 | — | 195 | 135 | 90 | 5.1 |

| 25 | 203 | 215 | 215 | 219 | 140 | 95 | 6.0 |

Note: * Weight corresponds to 250RF/300RF; other flange standards including DIN available on request, dimensions and weight may vary, contact TLV for details; 125FF can connect with 150RF, 250RF can connect with 300RF; ASME standards have no corresponding cast iron material, can only be paired with steel flanges.

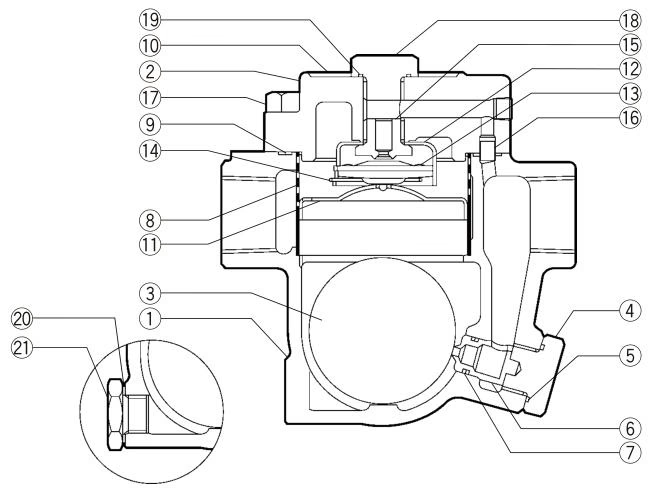

| No. | Mark | Component | Material | JIS | ASTM/AISI* |

|---|---|---|---|---|---|

| ① | Body | Ductile Iron/Cast Iron | FCD450/FCV400 | A536/A842 Gr.400 | |

| ② | Cover | Ductile Iron | FCD450 | A536 | |

| ③ⁿ | F | Float | Stainless Steel | SUS316L | AISI316L |

| ④ | Orifice Plug | Carbon Steel | S25C | AISI1025 | |

| ⑤ | MR | Plug Gasket | PTFE | PTFE | PTFE |

| ⑥ | R | Orifice | — | — | — |

| ⑦ | MR | Orifice O-Ring | Synthetic Rubber | EPR | D2000CA |

| ⑧ | R | Inner/Outer Strainer | Stainless Steel | SUS430/304 | AISI430/304 |

| ⑨ | MR | Cover Gasket | PTFE | PTFE | PTFE |

| ⑩ | Nameplate | Stainless Steel | SUS304 | AISI304 | |

| ⑪ | R | Float Guard | Stainless Steel | SUS304 | AISI304 |

| ⑫ | R | X-Element Guide | Stainless Steel | SUS304 | AISI304 |

| ⑬ | R | X-Element | Stainless Steel | — | — |

| ⑭ | R | Spring Clip | Stainless Steel | SUS304 | AISI304 |

| ⑮ | R | Air Vent Seat | Stainless Steel | SUS420F | AISI420F |

| ⑯ | Connector | Stainless Steel | SUS416 | AISI416 | |

| ⑰ | Cover Bolt | Carbon Steel | S45C | AISI1045 | |

| ⑱ | Plug | Carbon Steel | S25C | AISI1025 | |

| ⑲ | MR | Plug Gasket | PTFE | PTFE | PTFE |

| ⑳ | Drain Plug Gasket** | Soft Iron | SUYP | AISI1010 | |

| ㉑ | Drain Plug** | Carbon Steel | S25C | AISI1025 |

Note: (M) = Maintenance parts; (R) = Repair parts; (F) = Float

Explore similar products in our catalog