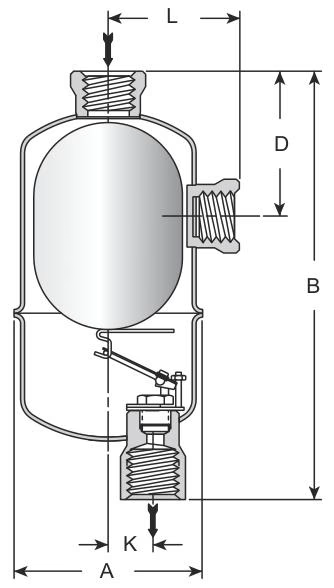

Armstrong free floating lever liquid drain trap, constructed with stainless steel, maximum pressure differential up to 3.9MPa, sufficient capacity, sealed anti-vibration design ensures stable operation, suitable for various working conditions, reliable quality and precise structure.

Armstrong 11-LD/22-LD/13-LD free floating lever liquid drain traps are premium industrial valve products from Armstrong, featuring a proven reliable design validated through years of use, sharing core component structures with quality-stable inverted bucket steam traps to ensure product performance and durability. The product features a sealed anti-vibration construction, with an elliptical float ball combined with a high-force lever design that opens large valve orifice diameters to meet sufficient flow requirements under various working conditions, suitable for applications below 3.9MPa pressure.

| Model | Nominal Diameter DN | A(mm) | B(mm) | D(mm) | K(mm) | L(mm) |

|---|---|---|---|---|---|---|

| 11-LD | 15, 20, 20*▲ | 70 | 184 | - | 14 | - |

| 22-LD | 20 | 100 | 224 | 76 | 22 | 67 |

| 13-LD | 25 | 114 | 289 | 156 | 30 | 83 |

| Model | Weight(kg) |

|---|---|

| 11-LD | 0.79 |

| 22-LD | 1.5 |

| 13-LD | 3.4 |

| Model | Disc and Seat | Lever System | Float Ball | Body and Cover | Gasket |

|---|---|---|---|---|---|

| 11-LD | Stainless Steel | Stainless Steel | Stainless Steel | Sealed Stainless Steel 304L | - |

| 22-LD | Stainless Steel | Stainless Steel | Stainless Steel | Sealed Stainless Steel 304L | - |

| 13-LD | Stainless Steel | Stainless Steel | Stainless Steel | Sealed Stainless Steel 304L | - |

Note: For components not explicitly specified in the table, please consult the manufacturer for special material configurations.

| Model | Maximum Allowable Pressure (38°C) | Maximum Allowable Pressure (260°C) |

|---|---|---|

| 11-LD | 3.5MPa | 3.0MPa |

| 22-LD | 4.1MPa | 3.3MPa |

| 13-LD | 3.9MPa | 3.4MPa |

Note: In some cases, shell design pressure may exceed float ball pressure capacity. Please follow relevant operating specifications during use.