Spirax Sarco BPT13 series repairable pressure balanced thermostatic steam traps, brass body design, includes angle connection/straight connection models, adaptable to different pipeline requirements. Precise drainage, high temperature and pressure resistance, excellent sealing performance, easy installation and maintenance, suitable for various industrial steam systems.

Spirax Sarco BPT13 series are repairable pressure balanced thermostatic steam traps, manufactured with brass bodies, featuring compact structure, stable performance, and reliable sealing. The standard model is BPT13A (angle connection), with various derivative models available, covering angle connection/straight connection, built-in filter, union inlet, and other configurations, flexibly adaptable to installation requirements of various industrial steam systems. The product achieves efficient drainage through precise thermostatic control, effectively avoiding steam waste and ensuring stable system operation.

| Capsule Model | Drainage Trigger Condition | Description |

|---|---|---|

| STD Type (Standard) | 12℃ below saturated steam temperature | Default configuration, suitable for normal conditions |

| NTS Type (Optional) | 4℃ below saturated steam temperature | For high-precision drainage requirements |

| SUB Type (Optional) | 24℃ below saturated steam temperature | For specific low-temperature drainage scenarios |

Note: Capsule type must be clearly specified when ordering to avoid affecting performance.

| Model | Connection Type | Special Configuration |

|---|---|---|

| BPT13A | Angle Connection | - |

| BPT13AX | Angle Connection | Built-in Filter |

| BPT13UA | Angle Connection | Union Inlet |

| BPT13S | Straight Connection | - |

| BPT13SX | Straight Connection | Built-in Filter |

| BPT13US | Straight Connection | Union Inlet |

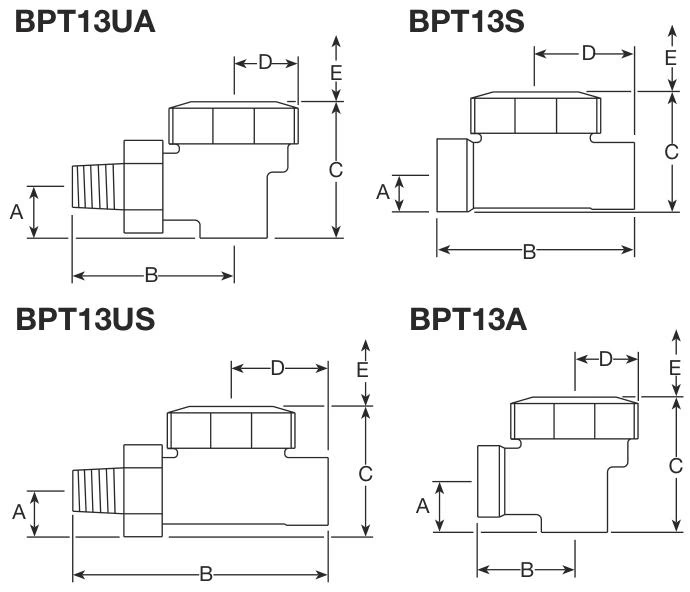

| Model | Port Size | Dimension A | Dimension B | Dimension C | Dimension D | Dimension E | Weight (Approx.) |

|---|---|---|---|---|---|---|---|

| BPT13A | ½" | 20 | 38 | 53 | 25 | 55 | 0.40 |

| BPT13A | ¾" | 27 | 40 | 62 | 25 | 55 | 0.45 |

| BPT13S | ½" | 14 | 76 | 47 | 38 | 55 | 0.45 |

| BPT13S | ¾" | 20 | 80 | 53 | 40 | 55 | 0.50 |

| BPT13UA | ½" | 20 | 67 | 53 | 25 | 55 | 0.50 |

| BPT13UA | ¾" | 27 | 75 | 62 | 25 | 55 | 0.55 |

| BPT13US | ½" | 19 | 105 | 52 | 38 | 55 | 0.55 |

| BPT13US | ¾" | 22 | 115 | 57 | 40 | 55 | 0.60 |

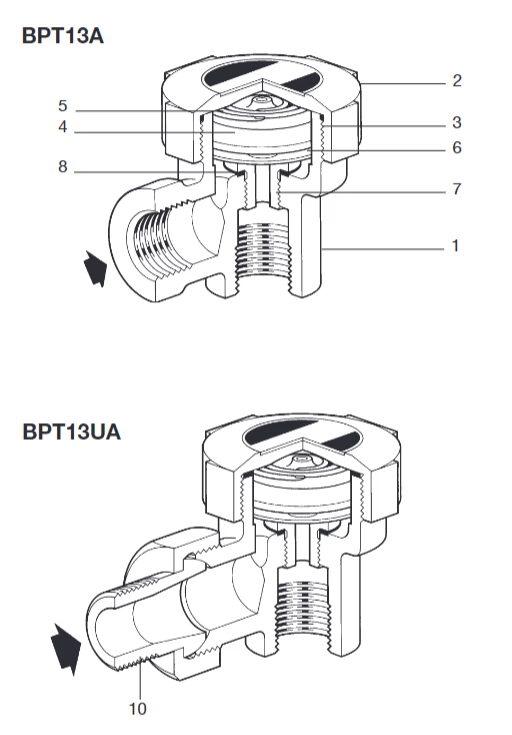

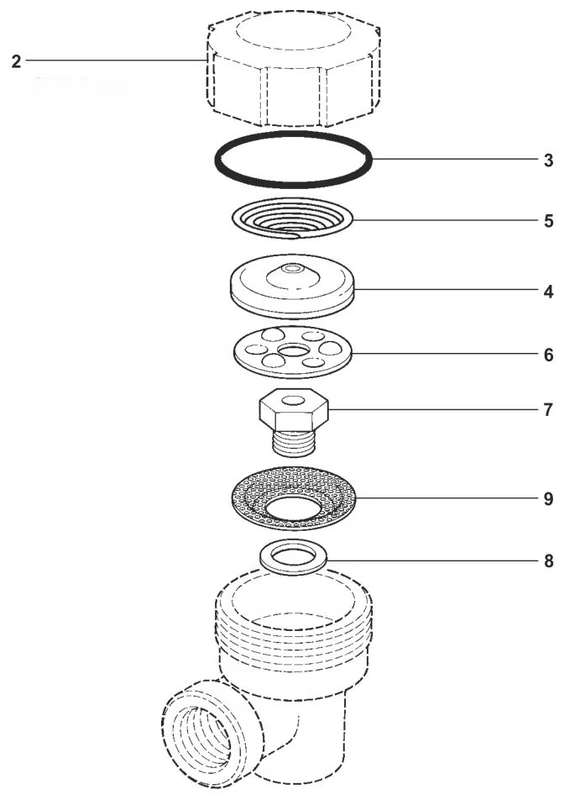

| No. | Component Name | Material Specification |

|---|---|---|

| 1 | Body | Brass (BS EN 12165 CW 617N) |

| 2 | Cap | Brass (BS EN 12165 CW 617N) |

| 3 | O-Ring | Synthetic Rubber Fluorocarbon |

| 4 | Capsule | Stainless Steel |

| 5 | Spring | Stainless Steel (BS 2056 302 S26) |

| 6 | Baffle | Stainless Steel (BS 1449 304 S16) |

| 7 | Valve Seat | Stainless Steel (BS 970 431 S29) |

| 8 | Valve Seat Gasket | Stainless Steel (BS 1449 304 S11) |

| 9 | Filter (*Optional) | Stainless Steel |

| 10 | Union Nut and Tail Pipe | Brass (BS EN 12165 CW 617N) |

Note: Part No. 9 is the built-in filter component, standard only for BPT13AX and BPT13SX models.

The BPT13 series steam traps provide stable condensate discharge capability, covering pressure differential conditions from 0.1-13bar, with maximum condensate discharge up to 2000kg/h (specific discharge depends on actual pressure differential and water temperature). The product efficiently discharges cold and hot condensate, avoiding efficiency reduction or equipment damage caused by water accumulation in pipelines, suitable for medium and low-pressure steam system drainage requirements.

| Component Name | Size Specification | Tightening Torque Range (Nm) |

|---|---|---|

| O-Ring | 50A/F | 50-60 |

| Cap Gasket | 50A/F | 90-110 |

| Valve Seat | 17A/F | 35-40 |

| Spare Part Name | Specification Description | Quantity Configuration |

|---|---|---|

| Capsule and Valve Seat Assembly | Includes Part 3 (O-Ring), 4 (Capsule), 5 (Spring), 6 (Baffle), 7 (Valve Seat), 8 (Valve Seat Gasket), 9 (Filter) | 1 Set |

| Cap Gasket (Early Models) | Standard Gasket Type | 3 Pieces |

| Cap Gasket (Current Models) | O-Ring Type | 3 Pieces |

| Filter | For Models with Filter | 3 Pieces |

The product can provide supplier test reports. If related certificates are required, they must be clearly specified when ordering.

1-Spirax Sarco ½" BPT13AX Pressure Balanced Steam Trap, BSP threaded connection, brass body with built-in filter, STD type capsule (drains when 12℃ below saturated steam temperature).

Explore similar products in our catalog